Handheld laser vuam tshuab Ib feem ntawm lub laser vuam vuam rooj plaub zaub

Ua hauj lwm hauv paus ntsiab lus editing tshaj tawm

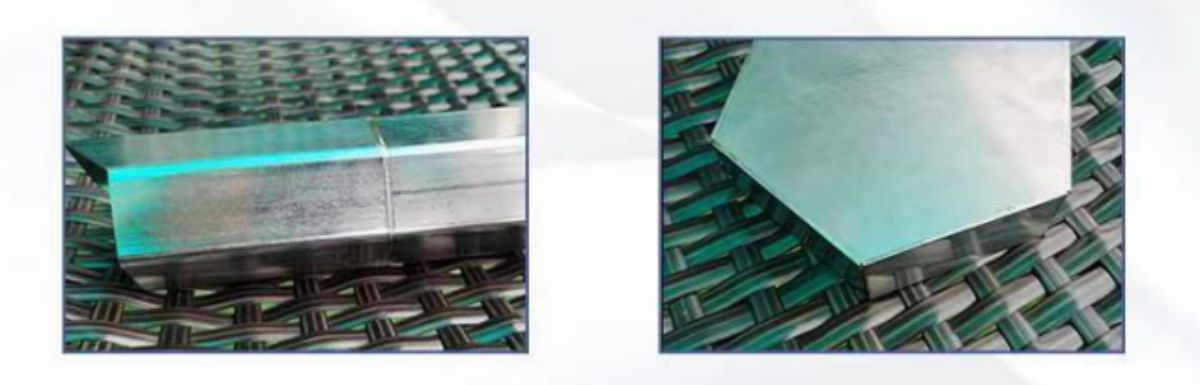

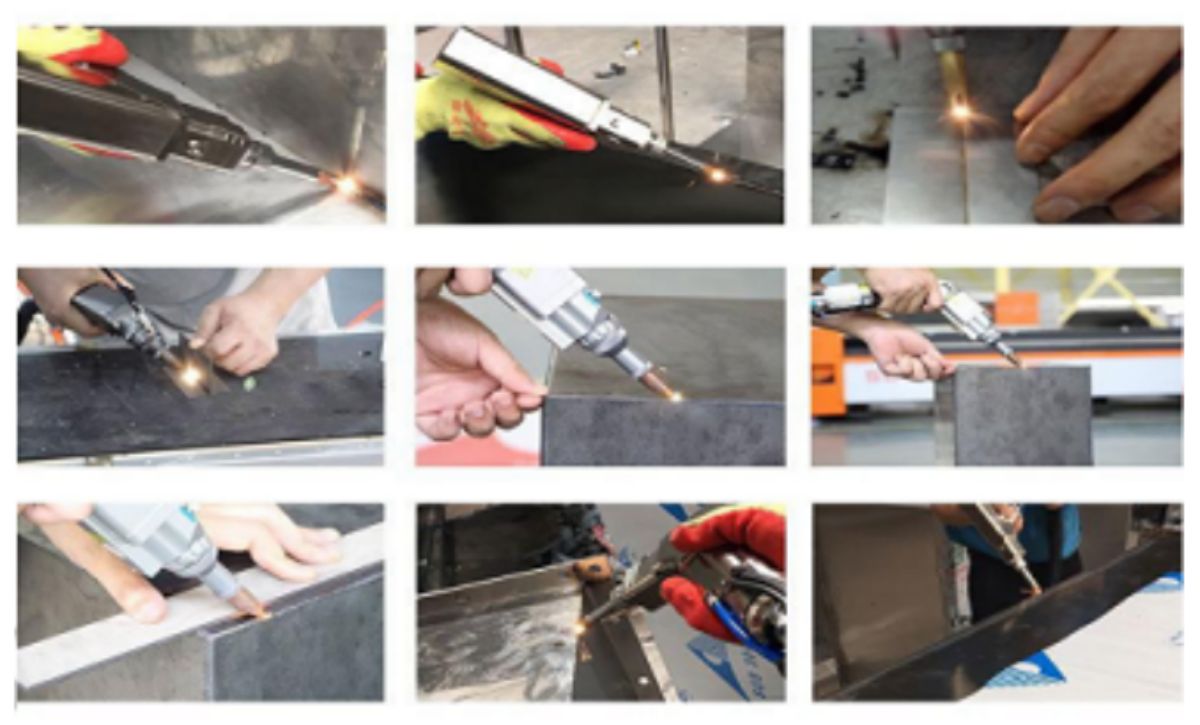

Laser vuam yog siv high-zog laser pulses los ua cov cua sov hauv zos nyob rau hauv micro cheeb tsam nrog high-zog laser pulses.Lub zog ntawm laser hluav taws xob yog ua los ntawm melting cov khoom los ntawm lub sab hauv diffusion ntawm thermal qhia cov ntaub ntawv los tsim ib tug tshwj xeeb melting pas dej ua ke.Nws yog ib yam tshiab ntawm txoj kev vuam.Nws yog tsuas yog tsom rau kev vuam ntawm nyias-walled cov ntaub ntawv thiab precision qhov chaw.Nws muaj peev xwm paub qhov taw tes vuam, txuas vuam, stacked vuam, sealing vuam, thiab lwm yam. Qhov sib sib zog nqus sib sib zog nqus yog siab, qhov vuam dav me me, cov cua sov cuam tshuam rau thaj tsam me me, thiab cov cua sov cuam tshuam rau thaj tsam me me.Me me deformation, vuam ceev ceev, tiaj vuam seams thiab zoo nkauj, tsis muaj kev kho mob tom qab vuam los yog tsuas yog ua, siab weld zoo, tsis muaj pores, raug tswj, me me lub teeb ntsiab lus, siab positioning raug, thiab yooj yim mus cuag automation.

Qhov tseeb, yuav muaj kev muag khoom zoo heev rau cov khoom siv vuam zoo li no, uas muaj ntau yam ua rau nws cov yam ntxwv, thiab cov yam ntxwv no feem ntau cuam tshuam nrog cov hauv qab no.

Nta 1: Vuam ua hauj lwm efficiency siab.Ntau cov khoom siv vuam tsoos kuj tuaj yeem ua rau muaj kev cuam tshuam zoo dua hauv kev siv tiag tiag, tab sis vim tias kev ua haujlwm ua haujlwm qeeb qeeb thaum thov, cov ntawv thov tau maj mam tau txais tsawg dua.Lub tshuab laser vuam tsis zoo ib yam.Koj yuav tsum paub tias qhov ua tau zoo ntawm kev ua haujlwm vuam coj los ntawm cov khoom siv no yog qhov siab heev.Nws yog ib qho tseem ceeb kom tswj tau ib qho kev huv huv thaum lub sij hawm tag nrho cov txheej txheem vuam.

2.Welding nyhuv yog pom tseeb.Rau qee qhov vuam nyuaj workpieces, nws yog ib qho tsim nyog yuav tsum siv cov cuab yeej vuam siab heev.Vim tias cov cuab yeej siv qib siab tuaj yeem ua tiav cov txiaj ntsig zoo dua vuam thaum lub sijhawm ua ntawv thov, thiab nws tsis muaj kev cuam tshuam rau lub ntsej muag ntawm lub workpiece.Laser vuam tshuab yog cov cuab yeej zoo li no, yog li ntau zaus thaum lawv ntsib cov khoom ua haujlwm uas muaj teeb meem vuam nyuaj, tib neeg xaiv siv hom khoom siv no.

Parameter:

| Qauv | EC-1500/2000 |

| Laser zog | 1500W / 2000W |

| Laser wavelength | 1080nm 1064nm ± 5nm |

| Laser hom | Tib hom |

| Photoelectric conversion efficiency | 30% |

| Hom haujlwm | tsis tu ncua |

| Fiber ntev | 10 m |

| Hom cua txias | Dej txias |

| Cooler qauv | 1500W / 2000W |

| Cov dej txias txias | 20-25 ℃ |

| Fais fab mov | AC220 AC380 ± 10%, 50 / 60Hz |

| Ua haujlwm kub | 10 ~ 35 ℃ |

| Ua hauj lwm ib puag ncig humidity | ≤ 95% |

| Kev hloov kho lub zog | 5-95% |

| Lub zog tsis ruaj khov | ≤ 2% |

| Transmission fiber core txoj kab uas hla | 25-50 hli |

Daim ntawv thov:

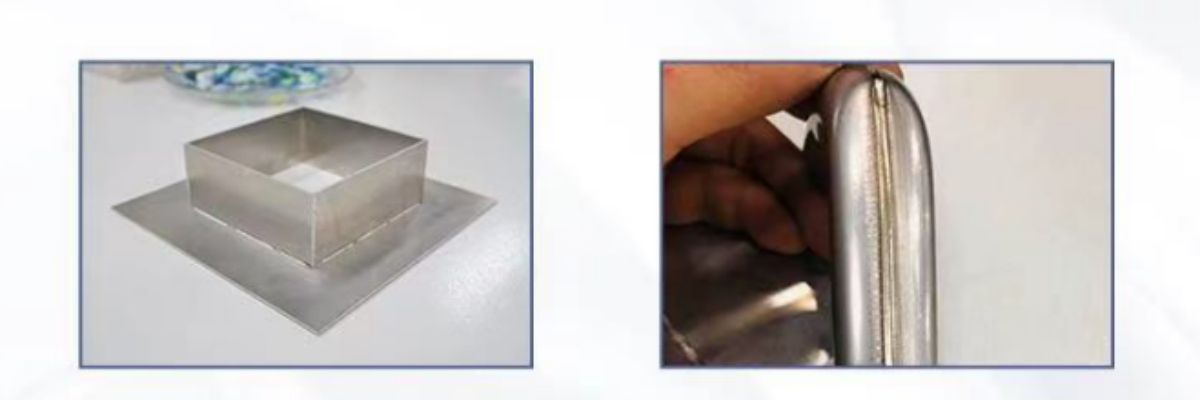

Cov khoom siv huv huv hauv thaj chaw ntawm chav dej huv, vuam vuam vuam ntawm cov kav dej, kev sib txuas ntawm lub tshuab hluav taws xob, peb txoj kev, rooj vag li qub, thiab cov da dej da dej.

Kev lag luam iav ntau lawm: high-precision vuam vuam ntawm stainless hlau daim hlau, aluminium alloy thiab lwm yam ntaub ntawv xws li cov qauv, ciam teb thiab lwm qhov chaw ntawm tus ncej.

Kev lag luam kho vajtse: centrifugal impeller, teapot, qhov rooj kov, thiab lwm yam., vuam vuam ntawm nyuaj hardware stamping qhov chaw, cam khwb cia hlau qhov chaw.

Automobile manufacturing: tsheb cav lub tog raj kheej pads, hydraulic presses siab tingle vuam, tsheb spark plug vuam vuam, lim caij vuam vuam, thiab lwm yam.

Kev lag luam khoom siv kho mob: cov khoom siv kho mob, cov tshuab kho mob stainless hlau phaj voltage sealing qhov chaw, thiab vuam vuam ntawm cov khoom.

Kev lag luam hluav taws xob: sealing vuam nyob rau hauv nruab nrab relay, vuam vuam ntawm connectors connectors, thiab vuam vuam ntawm yas plhaub xws li xov tooj ntawm tes thiab MP3 thiab cov khoom.Lub tshuab hluav taws xob vuam vuam ntawm lub plhaub lub cev muaj zog thiab cov kab txuas txuas, qhov kho qhov muag fiber ntau adapter connector.

Cov khoom siv hauv tsev neeg, cov khoom siv hauv chav ua noj, chav dej huv, stainless hlau phaj qhov rooj rub tes, cov khoom siv hluav taws xob, sensors, moos, precision machinery, kev sib txuas lus, kos duab thiab lwm yam kev lag luam, lub tsheb hydraulic thiab lwm yam siab-siab tsis kam nyob rau hauv cov vuam no.

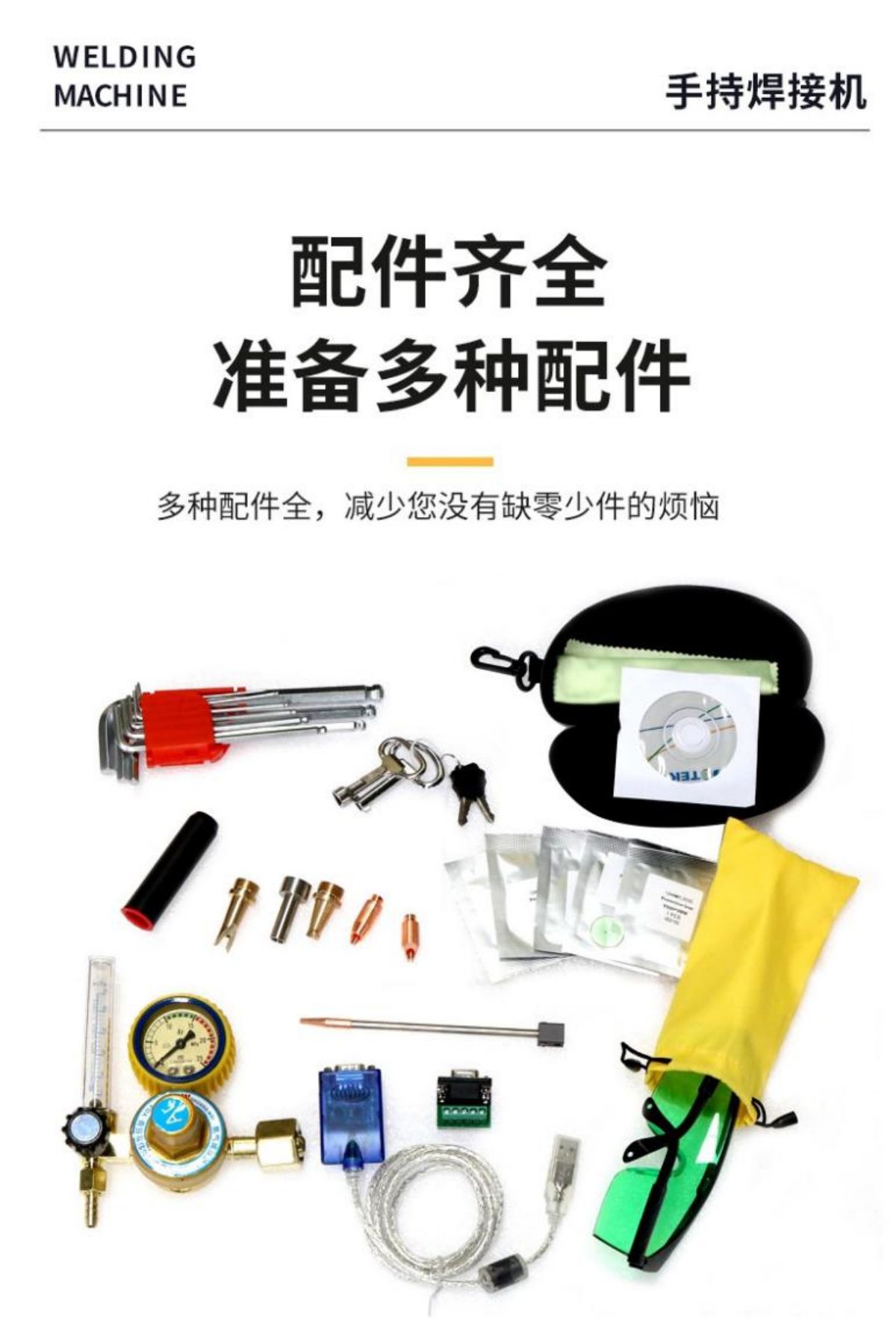

Ua kom tiav accessories

Lub tshuab tag nrho suav nrog cov khoom hauv qab no: vuam tshuab, xaim feeder, argon roj ntsuas, tsom iav, cov cuab yeej hexagonal, hnab looj tes, txhawb nqa nozzle, tiv thaiv lub lens.

| Lub npe | Quantity (set) | Hom lub npe |

| Laser ntaus ntawv | 1 |

|

| Laser taub hau | 1 |

|

| Dual kub dual tswj chiller | 1 |

|

| Lub zog hloov khawm | 4 | Yijia |

| Electromagnetic valve | 1 | Yadeke |

| AC contactor | 2 | Zhengtai |

| Master hloov | 1 | Delixi |

Lub warranty tag nrho ntawm lub tshuab vuam yog ib xyoos tshwj tsis yog rau lub txee.Laser lo ntsiab muag, welding torch lo ntsiab muag, thiab tooj liab nozzles yog qhov tsis zoo thiab tsis muaj kev tiv thaiv.