ECXT-6025 3000W fiber ntau laser txiav tshuab

Tshooj lus

Ua ntej, cov khoom nta

Kev siv ob sab servo lub cev muaj zog thiab kev taw qhia kev sib hloov mechanism, siab txiav raug, kev siv cov kev tshaj lij software, tuaj yeem tsim dawb los tsim ntau yam duab los nqa tawm lossis sau ntawv ua tiav, hloov pauv tau yooj yim, ua haujlwm yooj yim, yooj yim.Siv rau high-speed txiav, nrog kev kub ceev thiab ruaj khov.

1) Scope ntawm daim ntawv thov

Haum rau stainless hlau, carbon steel, alloy steel, silicon steel, galvanized steel phaj, npib tsib xee titanium alloy, inconel alloy, titanium alloy thiab lwm yam ntaub ntawv hlau.

Dav siv dav hauv aerospace, tsheb thiab nkoj, tshuab tsim khoom, kev tsim khoom of elevator, kev tshaj tawm kev tsim khoom, khoom siv hauv tsev, khoom siv kho mob, kho vajtse, kho kom zoo nkauj, hlau sab nraud kev pabcuam thiab lwm yam kev lag luam.

2) Qhov zoo ntawm fiber ntau laser txiav tshuab

1. Cov nqaj zoo heev: qhov chaw tsom me me, cov kab txiav yog qhov zoo dua, kev ua haujlwm zoo dua, thiab kev ua haujlwm zoo dua;

2, txiav ceev heev: yog tib lub zog CO2 laser txiav tshuab 2 zaug;

3, kev ruaj ntseg siab: kev siv lub ntiaj teb sab saum toj fiber ntau laser, kev ua haujlwm ruaj khov, cov khoom siv tseem ceeb ntawm kev pabcuam lub neej txog li 100,000 teev;

4. Tsis tshua muaj siab electro-optical conversion efficiency: fiber ntau laser txiav tshuab yog 2 zaug siab dua CO2 laser txiav electro-optical conversion efficiency, txuag hluav taws xob thiab kev tiv thaiv ib puag ncig;

5, tus nqi qis heev ntawm kev siv: lub zog noj ntawm tag nrho lub tshuab tsuas yog 20- ntawm CO2 laser tej tshuab zoo sib xws.

30;

6. Tsis tshua muaj nqi txij nkawm: tsis muaj laser ua haujlwm roj;Optical fiber ntau kis tau tus mob, tsis xav tau cov tsom iav tsom iav;Cov nqi kho mob tseem ceeb tuaj yeem ua tiav;

7, cov khoom lag luam thiab kev saib xyuas yog yooj yim: optical fiber kis tau tus mob, tsis tas yuav kho txoj kev kho qhov muag;

8.Super saj zawg zog lub teeb qhia cov nyhuv: me me, compact qauv, yooj yim hloov tau raws li qhov yuav tsum tau ua.

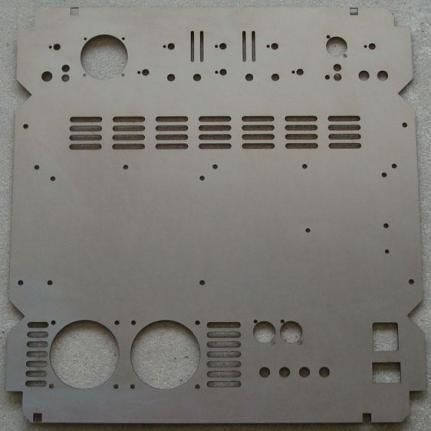

(3) Txiav cov qauv ua renderings

Thib ob, cov khoom siv tsis muaj

| Qauv | LFS6025-3000W |

| Chaw ua haujlwm | 6050 * 2550 hli |

| Max laser zog | 3000 W |

| Kho siab heev | Dav hlau taug qab |

| Yam tsawg kawg kab dav | 0.15 hli |

| Pulse zaus | 1-5000Hz |

| Rov ua dua | ± 0.02 hli |

| Taw rau qhov chaw | Lub teeb liab |

| Fais fab mov | 380V / 50Hz / 60Hz / 100A |

| Tshuab loj | 7880x3450x2000mm |

Thib peb, lub ntsiab configuration

Ordinal Number Name Model/Series Quantity Manufacturer Name.

| Tsis muaj. | Khoom npe | Qauv / series | Ntau | Chaw tsim tshuaj paus |

| Ib | Laser generator | |||

| 1 | Laser qhov chaw | 3000 wb | 1set ib | Kev sib koom tes tshawb fawb thiab kev tsim kho |

| 二 | Sab nraud optical txoj kev thiab txiav lub taub hau | |||

| 1 | Laser txiav taub hau | auto focus | 1set ib | Jiaqiang |

| ḉ | Tshuab cuab yeej host | |||

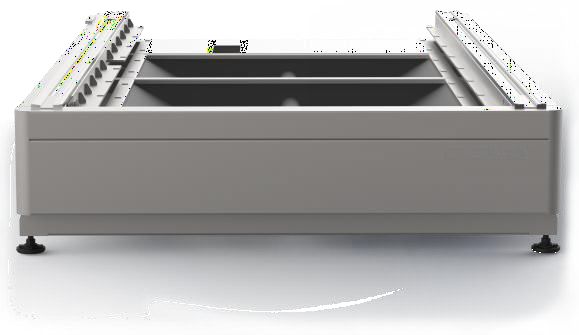

| 1 | Tshuab txaj | 6025 ib lub platform | 1set ib | Zoo heev Mechanical |

| 2 | Linear Guides | HGL HA2R | 2set ib | Taiwan King TEK |

| 3 | Servo lub cev muaj zog thiab tsav tsheb | 4set ib | Nyiv Fuji | |

| 4 | XY axis planetary reducer | PAB-090 | 3set ib | Fabkis Mordry |

| 5 | Helical iav / khib | YYC 2 M | 2set ib | YYC |

| 6 | Tswj txee | 1set ib | Zoo heev Mechanical | |

| 7 | Tshuab cuab yeej accessories | 1set ib | Zoo heev Mechanical | |

| Plaub | CNC thiab software system | |||

| 1 | CNC system | Bai chu | 1set ib | Suav Bai chu |

| 2 | Kev lag luam computer | 1set ib | Customized | |

| 3 | Cov khoom siv hluav taws xob | 1set ib | Schneider | |

| Tsib | Txheem accessories | |||

| 1 | Precision Chiller | HL-3000 | 1 tsi | Wuhan Hanli |

| 2 | Tsis siv neeg roj filling system | 1set ib | hluav taws xob | |

| 3 | Muaj qhov kub thiab txias cua txias | 1set ib | ||

| 4 | Exhaust system | 1set ib | pipeline reservation | |

| 5 | Stabilizer | 1set ib | customized | |

| 6 | Txais trolley | 1set ib | customized | |

| Rau | Kev khiav hauj lwm lub ntsiab efficiency | |||

| 1 | Max ceev | 1.2g ua | ||

| 2 | Kev khiav hauj lwm lub ntsiab efficiency | 120m / min | ||

Plaub, txiav txheej txheem parameter rooj

| Hom khoom | Thickness (mm) | Ceev (m / min) | tsom xam txoj hauj lwm | Txiav qhov siab (mm) | Roj | Nozzle Hom | Cua siab (bar) | Laser zog (W) | txiav zaus (Hz) | Lub luag haujlwm voj voog% | txiav nyhuv |

|

q235 ib Cov pa roj carbon steel | 1 | 38-40 : kuv | 0 ~ 0.5 hli | 0.5 | N2 | ib txheej 1.0 | 12-16 : kuv | 3000 | 5000 | 100 | Glossy |

| 2 | |||||||||||

| 3 | 4 ~ 4.2 | 4.5 ~ 5.5 hli | 0.8 ua | O2 | ob txheej: 1.0 | 0.6 ~ 0.9 hli | 3000 | 5000 | 100 | ||

| 4 | 3.3 ~ 3.5 hli | 4.5 ~ 5.5 hli | 0.8 ua | O2 | ob txheej: 1.2 | 0.6 ~ 0.9 hli | 3000 | 5000 | 100 | ||

| 6 | 2.3 ~ 2.5 hli | 4.5 ~ 5.5 hli | 0.8 ua | O2 | ob txheej: 1.2 | 0.6 ~ 0.9 hli | 3000 | 5000 | 100 | ||

| 8 | 2.1 ~ 2.2 | 4.5 ~ 5.5 hli | 0.8 ua | O2 | ob txheej: 1.2 | 0.6 ~ 0.9 hli | 3000 | 5000 | 100 | ||

| 10 | 1.5 ~ 1.7 hli | 2 ~ 3 | 1.5 | O2 | ob txheej: 3.0 | 0.6 ~ 0.9 hli | 2200-2400 Nws | 5000 | 100 | 磨砂面 | |

| 12 | 1.2 ~ 1.4 hli | 2 ~ 3 | 1.5 | O2 | ob txheej: 3.0 | 0.6 ~ 0.9 hli | 2200-2400 Nws | 5000 | 100 | ||

| 14 | 1 ~ 1.1 | 2 ~ 3 | 1.5 | O2 | ob txheej: 4.0 | 0.6 ~ 0.9 hli | 2200-2400 Nws | 5000 | 100 | ||

| 16 | 0.85 ~ 0.9 hli | 2 ~ 3 | 1.5 | O2 | ob txheej: 4.0 | 0.6 ~ 0.9 hli | 2200-2400 Nws | 5000 | 100 | ||

| 18 | 0.7-0.75 Nws | 2 ~ 3 | 1.5 | O2 | ob txheej: 4.0 | 0.6 ~ 0.9 hli | 2200-2400 Nws | 5000 | 100 | ||

| 20 | 0.6 ~ 0.65 hli | 2-3.5 Nws | 1.5 | O2 | ob txheej: 4.0 | 0.6 ~ 0.9 hli | 2200-2400 Nws | 5000 | 100 | ||

| 22 | 0.5 ~ 0.55 hli | 2-3.5 Nws | 1.5 | O2 | ob txheej: 4.0 | 0.6 ~ 0.9 hli | 2200-2400 Nws | 5000 | 100 | ||

| 25 | 0.45 ~ 0.5 hli | 2-3.5 Nws | 1.5 | O2 | ob txheej: 5.0 | 0.6 ~ 0.9 hli | 2200-2500 Nws | 5000 | 100 | ||

| SUS 304 不锈钢 | 1 | 35-37 : kuv | 0 ~-1 | 0.5 | N2 | Ib txheej: 1.0/1.2/1.5 | 12-16 : kuv | 3000 | 5000 | 100 | 无渣 |

| 2 | 13-15 : kuv | -1.5 ~ 2 | 0.5 | N2 | Ib txheej: 1.5 / 2.0 | 12-16 : kuv | 3000 | 5000 | 100 | ||

| 3 | 7 ~ 8 | 2.5 ~ 3 | 0.5 | N2 | Ib txheej: 2.0/2.5/3.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 4 | 4.5 ~ 5.5 hli | -3.5 ~ 4 | 0.5 | N2 | Ib txheej: 3.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 6 | 1.7-1.9 Nws | -5-5.5 | 0.5 | N2 | Ib txheej: 3.5/4.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 8 | 0.8 ~ 1.0 | -6 ~ 7 | 0.5 | N2 | Ib txheej: 4.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 10 | 0.6 ~ 0.7 hli | 7.5 ~ 8.5 | 0.5 | N2 | Ib txheej: 4.0 | 16-20 : kuv | 3000 | 5000 | 100 | 少量挂渣 | |

| AL 铝 (6061) | 1 | 30-33 : kuv | -0.5 ~ 1 | 0.5 | N2 | Ib txheej: 1.0/1.2/1.5 | 12-16 : kuv | 3000 | 5000 | 100 | |

| 2 | 10 ~ 12 | -1 ~ 1.5 | 0.5 | N2 | Ib txheej: 1.5 / 2.0 | 12-16 : kuv | 3000 | 5000 | 100 | ||

| 3 | 5.5 ~ 5.9 hli | 2.5 ~ 3 | 0.5 | N2 | Ib txheej: 2.0/2.5/3.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 4 | 2.8 ~ 3.2 hli | -3.5 ~ 4 | 0.5 | N2 | Ib txheej: 3.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 6 | 0.7 ~ 0.8 hli | -5-5.5 | 0.5 | N2 | Ib txheej: 3.5/4.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 8 | 0.5 ~ 0.6 hli | -6 ~ 7 | 0.5 | N2 | Ib txheej: 4.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 黄铜 | 1 | ||||||||||

| 2 | |||||||||||

| 3 | 4.5 ~ 5 | 2-2.5 | 0.5 | N2 | Ib txheej: 2.0/2.5/3.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 4 | 3 ~ 3.5 | 3-3.5 | 0.5 | N2 | Ib txheej: 3.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 5 | |||||||||||

| 6 | 1 ~ 1.2 | -5-5.5 | 0.5 | N2 | Ib txheej: 3.5/4.0 | 16-20 : kuv | 3000 | 5000 | 100 | ||

| 8 | |||||||||||

| 备注 | 1, Nyob rau hauv cov ntaub ntawv txiav, cov tub ntxhais txoj kab uas hla ntawm cov zis fiber ntau ntawm 3000W laser yog 100 microns; | ||||||||||

| 2, Cov ntaub ntawv txiav no siv Jiaqiang txiav lub taub hau, qhov sib piv qhov muag yog 100/125 (collimation / tsom iav focal ntev) ; | |||||||||||

| 3, Txiav auxiliary gas: kua oxygen (purity 99.6%) kua nitrogen (purity 99.995%); | |||||||||||

| 4, Vim yog qhov sib txawv ntawm cov khoom siv teeb tsa thiab cov txheej txheem txiav (lub tshuab cuab yeej, dej txias, ib puag ncig, txiav cov roj nozzle thiab roj siab, thiab lwm yam) tau txais los ntawm cov neeg siv khoom sib txawv, cov ntaub ntawv no tsuas yog siv rau kev siv xwb. | |||||||||||

5. Cov cuab yeej siv tshuab thiab cov khoom siv tseem ceeb

(1)

Lub txaj txaj tau txais cov qauv patented ntawm Chaoxing Group, thiab tag nrho cov laus kev nyuaj siab nyem kev kho mob yog ua tiav los ntawm ib-lub sij hawm precision machining ntawm ib tug loj machining chaw los xyuas kom meej siab rigidity, precision thiab stability;

(2) Gear racks thiab coj rails

Khib thiab pinion: Taiwan precision helical khib thiab pinion, P-class linear qhia raws li kis tau tus mob, siab precision thiab siab ceev.

Kev taw qhia rails: Taiwan linear guides yog siv, thiab hnyav-duty precision linear guides nrog optimized structural tsim yog kev koom ua ke.Piv nrog rau lwm cov kab ntawv qhia, lub load thiab rigidity yog txhim kho;nws muaj qhov zoo ntawm kev kub ceev, siab load, siab rigidity thiab siab precision.

(2) Servo lub cev muaj zog

Siv Japanese servo motors, nws muaj qhov zoo dynamic teb acceleration, thiab paub txog qhov muaj peev xwm ntawm qhov chaw siab.High stability, siab precision thiab txij nkawm-dawb.

(4) Reducer

Txais yuav imported reducer.

qhov zoo:

High precision: backlash tsawg dua 3 arc feeb, qhov tseeb qhov chaw.

High rigidity, siab torque: Kev siv cov menyuam bearings zoo heev txhim kho rigidity thiab torque.

Tsis Muaj Roj Leakage: Siv cov roj viscosity siab, sib cais roj kom zoo tiv thaiv cov roj to.

Kev saib xyuas yooj yim: tsis tas yuav hloov roj thaum lub neej ntawm cov khoom.

(5) Fiber laser generator

Xaiv qhov kev tshawb fawb sib koom ua ke thiab txhim kho fiber ntau laser generator, qhov zoo ntawm lub tshuab hluav taws xob laser:

▲ High electro-optical conversion tus nqi

▲ Cov nqaj zoo heev

▲ Lub neej ua haujlwm ntev

▲ Tus nqi qis ntawm kev siv dav

▲ Kev kho tsis pub dawb

6) Nta ntawm fiber ntau laser taub hau:

1. Txais QBH interface, uas tuaj yeem hloov kho rau txhua qhov fiber ntau lasers tso zis los ntawm QBH connector.

2. Cov plua plav pov thawj tsim ntawm collimating tiv thaiv daim iav tsim los ntawm invention patent.

3. Tsis siv neeg tsom xam hloov, ceev ceev, siab precision thiab yooj yim ua hauj lwm.

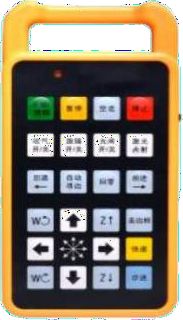

(7) Kev tswj qhov system:

CNC tswj system muaj cov khoom tseem ceeb xws li PC tswj qhov system, tus tsav tsheb thiab nws cov servo lub cev muaj zog.Qhov tshwj xeeb laser CNC system yog saws, uas sawv cev rau cov kws tshaj lij laser ua CNC system.Lub compact thiab modular CNC ua tau raws li cov kev xav tau ntawm cov neeg siv khoom siv high-performance CNC systems nrog nws cov nqi zoo / kev ua tau zoo.

Superior kev ua tau zoo:

Ø First-class technology thiab efficiency

CNC thev naus laus zis tshiab thiab qhib CNC architecture nrog Intel dual-core CPUs muab cov neeg siv yooj yim dua hauv kev xaiv CNC qhov chaw thiab ib-kauj ruam ua ntej CNC kev ua tau zoo.

Ø Modular qauv

lHigh-speed machining

lHigh-speed tshuab cov cuab yeej yuav tsum tau luv luv lub voj voog lub sij hawm (PA mus txog 7200 blocks / sec) thiab tshwj xeeb tswj algorithms thiab kev sib txuas lus ua haujlwm."Adaptive pre-reading function" yuav ua ntej txheej txheem 1000 blocks hauv lub sijhawm tiag tiag, thiab suav tus nqi pub ntau tshaj nyob rau hauv qhov programming tsis thiab txwv kom tau raws li qhov yuav tsum tau ua ntawm kev ua haujlwm nyuaj.

Ø Qhov tseeb

Cov kev xav tau rau kev tsim khoom siab, siab precision thiab zoo nto tiav zoo yog nce ntxiv.

Ø Tib neeg-tshuab interface

Kev tshuaj ntsuam xyuas ua haujlwm kom pom sai sai;ntau yam kev txiav cov pa roj tuaj yeem hloov tau yooj yim los ntawm kev tswj cov lej.

Nws muaj cov kws tshaj lij laser txiav cov txheej txheem parameter lub tsev qiv ntawv thiab cov neeg siv khoom tus phooj ywg cov kws tshaj lij lub tsev qiv ntawv tsis muaj qhov cuam tshuam, uas tuaj yeem hloov kho cov txheej txheem laser txiav hauv lub sijhawm tiag tiag hauv kev sib tshuam.

Ethernet kev sib txuas lus interface tuaj yeem sib txuas lus ncaj qha nrog lub khoos phis tawj thiab hloov cov ntaub ntawv ib feem.Nrog cov xwm txheej tso saib thiab tso saib ua haujlwm ntawm txoj haujlwm tam sim no.

Lub hard disk chaw cia yog 250G, thiab cov txheej txheem ua haujlwm tuaj yeem hu ncaj qha los ntawm hard disk, yog li nws tsis txwv los ntawm lub cim xeeb ntawm lub system.Kev kuaj mob chaw taws teeb muaj nuj nqi, digital servo system.Xim LCD zaub.

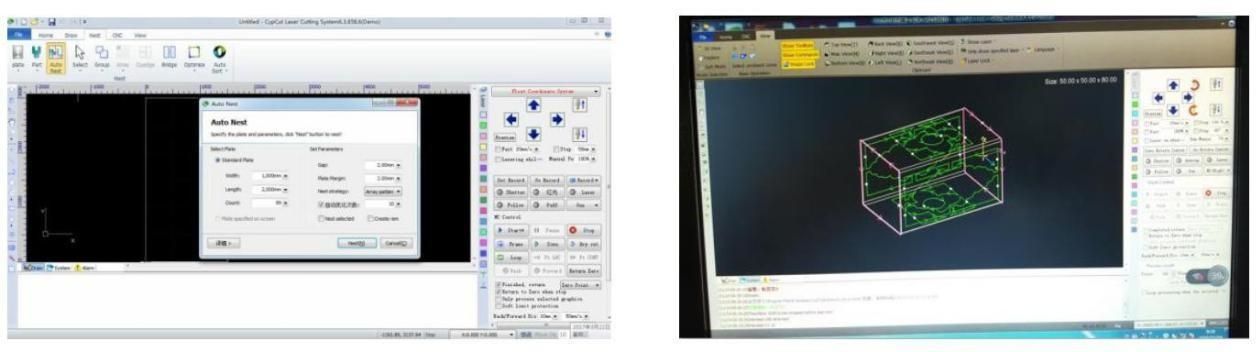

(8) Kev tsim thiab tsim software nesting

Cypcut thiab Cuytube yog lub zog hlau txiav tshuab thiab txawj ntse ntaus ntawv software, suav nrog cov txheej txheem laser txiav, kev ua haujlwm zes thiab kev tswj xyuas laser.Lub luag haujlwm tseem ceeb suav nrog kev ua cov duab kos duab, kev teeb tsa parameter, kev cai txiav cov txheej txheem kho, layout, txoj kev npaj, simulation, thiab txiav cov txheej txheem tswj.

9) Cua txias system

Txais Wuhan Hanli chiller system kom txias lub tshuab hluav taws xob laser, ua kom txias cov khoom siv kho qhov muag thiab lub taub hau txiav.Lub tshuab cua txias muaj qhov kaw-voj dej txias Circuit Court.

(10) Muaj cua txias

Lub tshuab cua txias siab siab siab siv tau los ua kom muaj huab cua huv thiab qhov kub thiab txias hauv lub txee, kev txawj ntse tsis siv neeg tswj, ntse tswj raws li qhov ntsuas kub hauv lub txee, ob chav lim tiv thaiv, ua kom haum rau qhov chaw hnyav xws li ib puag ncig tsis zoo, siab plua plav, thiab kub kub.Zoo heev txhim kho lub neej kev pab cuam ntawm precision hluav taws xob Cheebtsam.

6. Kev Pabcuam

(1) Cov khoom siv ua haujlwm thiab ib puag ncig yuav tsum tau ua

| Tsis muaj. | Paub meej |

| 1 | Fais fab mov: 100KVA |

| 2 | Fais fab mov yuav tsum tau: (kev tswj fais fab mov yog pom zoo) Rated tso zis voltage: 380V / 50Hz Peb-theem voltage stability +10 Kev tswj cov zis hluav taws xob: <2 |

| 3 | Cov khoom siv cua compressed (ib lub tank cua tau pom zoo) Ntim: 0.6 m3 Rated siab: 20 bar |

1. On-site fais fab faib txee: 380V, 50Hz, peb-theem plaub-xaim, muaj peev xwm tsis pub tsawg tshaj 100 KVA, nrog rau kev tiv thaiv luv luv, thiab lwm yam.

2. Cov khoom siv yuav tsum tau nruab nrog tshwj xeeb hauv av, thiab nws cov av tiv thaiv yuav tsum tsis pub tshaj 4Ω.

3. Muab cov cuab yeej nqa thiab cov neeg ua haujlwm tsim nyog.

4. Muab cov ntaub ntawv xws li cov phaj hlau uas yuav tsum tau ua rau ntawm qhov chaw debugging ntawm cov khoom siv.

5. Muab ib ntus pass rau cov neeg ua haujlwm debugging.

6. Cov xwm txheej uas yuav tsum tau ua rau kev ua haujlwm ntawm cov khoom siv laser txiav: a.Txiav auxiliary gas (N2, O2);

b.Dej-dawb thiab roj-dawb compressed cua system.

7. Cov khoom siv qhov chaw thiab lub hauv paus xav tau: Lub hauv paus yog pob zeb.

(3) Kev teeb tsa thiab kev cob qhia

1. Kev teeb tsa:

Tsis pub dhau 30 hnub tom qab kos npe rau daim ntawv cog lus ua lag luam, muab cov neeg siv nrog cov kev npaj hauv pem teb (nrog rau cov kev xav tau rau kev teeb tsa kev ua haujlwm hauv pej xeem, dej, hluav taws xob, roj, piping, interfaces, thiab lwm yam).

Cov khoom siv tau nruab rau ntawm tus neeg siv lub Hoobkas, thiab tus neeg siv yuav tsum tau muab qhov chaw txaus, lub zog siv hluav taws xob thiab qhov cua nkag mus rau nruab cov khoom siv.Kev teeb tsa yog ua los ntawm tus neeg muag khoom tus kws tshaj lij engineers uas tau kawm tiav.Tus neeg muag khoom yog lub luag haujlwm rau kev teeb tsa cov cuab yeej (nrog rau kev teeb tsa ntawm cov kav dej) thiab kev debugging.Tus neeg siv yog lub luag haujlwm rau kev ua haujlwm hauv pej xeem ntawm kev teeb tsa cov khoom siv, thiab cov kav dej, cov kav dej roj, thiab cov kab hluav taws xob txuas nrog lub tshuab cuab yeej tsim los ntawm tus neeg muag khoom engineer, thiab Party B yog lub luag haujlwm rau cov kav dej txuas nrog lub tshuab cuab yeej, tab sis tus neeg siv yuav tsum muab tus neeg muag khoom tus engineer nrog kev koom tes tsim nyog thiab kev pab cuam rau kev teeb tsa thiab kev debugging.

2. Kev cob qhia:

Kev cob qhia cov neeg ua haujlwm tau ua tiav hauv cov neeg yuav khoom lub Hoobkas, feem ntau yog kawm cov khoom siv tu, kev ua haujlwm, kev tiv thaiv laser, kev siv thev naus laus zis, graphic editing, kev daws teeb meem, thiab lwm yam. Cov tub ntxhais kawm yuav tsum nkag siab txog kev ua haujlwm hauv computer thiab muaj qee yam kev paub txog AutoCAD kos duab.

(4) Tom qab kev muag khoom

1. Tom qab kev lees paub, lub sijhawm lav zoo ntawm tag nrho lub tshuab yog ob xyoos.Yog tias qhov chaw ntawm lub kaw lus muaj teeb meem zoo thaum lub sijhawm lav, peb lub tuam txhab kev pabcuam engineers tau txais kev pabcuam zoo yuav muab kev pabcuam hauv xovtooj lossis chaw pabcuam txhua lub sijhawm.Xov tooj teb hauv 2 teev

, kev pabcuam ntawm qhov chaw nyob hauv 24 teev.

2.Thaum lub sijhawm lav ntawm cov khoom siv, peb lub tuam txhab yog lub luag haujlwm rau kev hloov pauv dawb ntawm cov khoom thiab cov kev pabcuam rau kev puas tsuaj lossis kev puas tsuaj los ntawm qhov zoo ntawm cov khoom siv nws tus kheej, tshwj tsis yog cov khoom siv tau zoo (xws li optical lo ntsiab muag, nozzles) thiab cov uas. yog lub luag haujlwm rau tus neeg siv kev ua haujlwm tsis raug cai.

3.Sab nraum lub sij hawm lav ntawm cov khoom siv, peb lub tuam txhab cov kev pabcuam kev cob qhia zoo yuav muab kev pabcuam hauv xovtooj lossis chaw pabcuam txhua lub sijhawm.Xov tooj teb yog nyob rau hauv 2 teev thiab kev pabcuam teb hauv 48 teev.Yog tias qhov kev hloov pauv ntawm cov khoom seem raug cuam tshuam, peb lub tuam txhab yuav them tus nqi ntawm cov khoom raws li tus nqi lag luam, thiab koj yuav tau them tus nqi mus ncig ntawm peb lub tuam txhab cov kws kho tsheb.